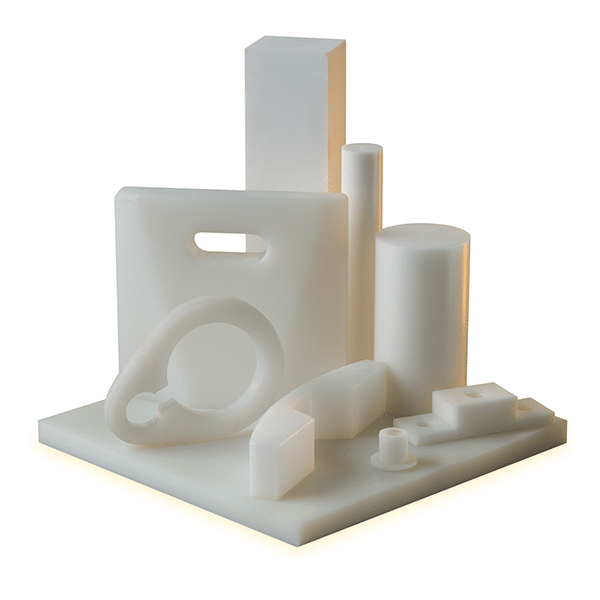

PVDF Engineering Plastic Components

This cycle of melting, reforming and cooling can be repeated task again and again. Injection molding is a production process that takes advantage of this. PVDF Engineering Plastic Components can be used to quickly and economically produce large numbers of consistently high-quality thermoplastic parts

PVDF Engineering parts

It is a high power plastic components for valves filter plates and fitting and pipe lines.High permanent operating temperature (140°C)PVDF has been used in piping and pumping applications, and is available in sheet, films, tubing, plate and as an insulator in high-quality wire.

UHMW Engineering Plastic Components

The Polymer Market place consists of a huge diversity of manufacturers of industrial products running many different processes yet still facing similar challenges. There is more and more pressure to achieve high product quality and reduce costs in order to stay one step ahead of the competition.

PTFE Engineering Plastic Components

devote analytical test and laboratory consumables to provide high quality, efficient service and favorable price. Due to its high power temperature rating and extreme non-reactivity, PTFE Engineering Plastic Components Plastic is often used as containers, expansion joints liners in hose assemblies, industrial pipelines, and other applications involving corrosive and reactive chemicals.

PEEK is a special skills in machining to obtain accurate dimensions. There are relative hardness, stresses within the moulded part and generally high rate of wear on the tool dictates the need for careful handling.

PEEK Engineering Plastic Components

More Info:

Contact-us-8218684097

Email-us-sales@petronthermoplast.com

No comments:

Post a Comment