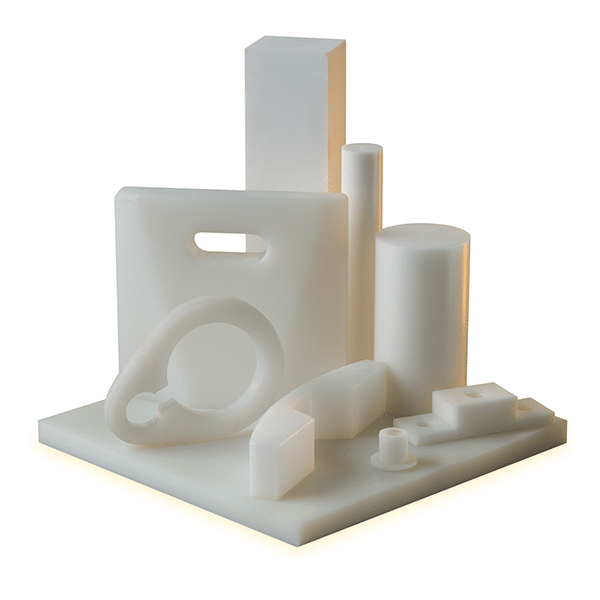

PVDF Engineering Plastic Components

The Plastic Compound is the process of plastic kneading various of PVDF Products Manufacturing company in India.

Optimal compounding solution and high manufacturing Technologies we can achieve excellent and Good Electrical ageing Properties, It is a high temperature resistance.

It is an ingredient in high-end paints for metals. These PVDF paints have extremely good gloss and color remembrance, As a good powder grade, They are in use on many prominent buildings around the world,

The main difference between them is how they react to heat, Add to value of natural resistance to fungus, ozone and weather, we are the most of one of leading part of pvdf manufacture company in india.

PVDF precision parts manufacturing company

It high product repeatability suitable for high and low volume order and easy process and method and good installing product quality, with our company advance provide competitive precision machining services and have been the preferred precision machine shop for business in many industires.

We are large range of PVDF sheet parts for Metalon Pipes, components Rods, nylon, You can understand market strategies ,It is a combine thease strategies client satisfaction terms & condition policy heat treatment of materials to improve reduce and strength internal stresses ,and controlled machining of processes to reduce or eliminate machining defects,

PVDF Engineering parts

The fluoropolymer family of plastics has multiple carbon-to-fluorine bonded sections inside each molecule, making them very resistant to solvents, acids, and bases. PVDF is resistant to a wide range of aggressive chemicals, including.

UHMW Machined part s for conveyor lines.in our life, Ultra-high molecular weight polyethylene

The machine parts of replacing metal part such as a chutes, wear strips, guides, and rollers. It provides excellent performance in packaging equipment applications.

UHMW Engineering Plastic Components

We can be specialize in highly complex integrated structures and applications requiring very specific mechanical, thermal, or dimensional specifications

.Our unique Liquid Resin Molding processes,Its high abrasion resistance and excellent wear properties give it long working life, even in nonstop or high-cycle operations.it is good

Part of UHMW Engineering Plastic Components in

Engineering Technologies

We have a some long and distinguished record of supplying power conventional and unconventional shapes of PTFE in a wide area of variety of configurations. You can, of course, buy the stock shapes from us and do your own machining – but customers invariably find it more practical and satisfactory to have the machining and finishing operations carried out at our plant.

PTFE Engineering Plastic Components

When people think of non-stick coatings, they immediately think about non-stick pans, trays and tins that are used in backware and other components in the drink & food Industries And whilst our fluoropolymer non-stick coatings are often used in these industries, they can also be applied whole host of industries and components. Whatever the application, if you require non-stick or release properties, our coatings are the perfect solution.

These products have been used in different medical applications: Spinal, Trauma Fixation, Cardiovascular, Dental, Arthroscopy, Orthopedic, Analytical Equipment, Surgical Instruments, Prosthesis, and Veterinary.

PEEK Engineering Plastic Components

Peek Engineering plastic deal with medical science part Dental and Equipment surgical for etc. we are stock shapes provide customers with a quick and economical route for prototypes and scaling up to commercial manufacturing. Depending on volume, machined parts can also be a flexible platform for production parts with little to no capital investment.

ABC is most use of opaque thermoplastic and amorphous polymer.Its is a created albeit less commonly by formula mass polymerization. Globally, the most common methodology in industries

It is create a process Mechanisms uses the Fused Deposition Modeling 3D printing.

ABS Engineering Plastic Components

ABS is relatively safe to handle as it cools down and hardens making a good product ,ABS can be repeatedly melted down and reshaped without significant chemical degradation It is a very amazing and good process.

Engineering plastics are use bunch of plastics that are used most ordinarily in industries because of their enhanced mechanical and thermal properties. Engineering plastics are commonly used out of doors and It is now recognized that sunlight with a wavelength.

PVC Engineering Plastic Components

It is tow types of form rigid or unplasticized polymer (RPVC or uPVC), and the second as a flexible plastic. In its base form, PVC is characterized by its rigid yet brittle structure. PVC are offer a wide variety of application ,It is also readily available and economical, which, combined with most plastics' long-lasting characteristics, makes it an easy choice for many industrial applications like construction

Polypropylene is a very high customizable plastic since it can also be combined with other materials, such as rubber types of order to create an even stronger co-polymer, There are three general types of polypropylene homopolymer, random copolymer, and block copolymer. The comonomer is typically used with Ethylene Ethylene-propylene rubber

PP Engineering Plastic Components

one of most use of commodity plastic meterials injection modeling, pp plastic Components exhibit good resistance to rigidity and scratching with excellent dimensional stability.

Polypropylene Engineering Plastic Components has a relatively slippery surface which can make it a possible substitute for plastics like acetal (pom) in low friction applications like gears or for use as a contact point for furniture.

.